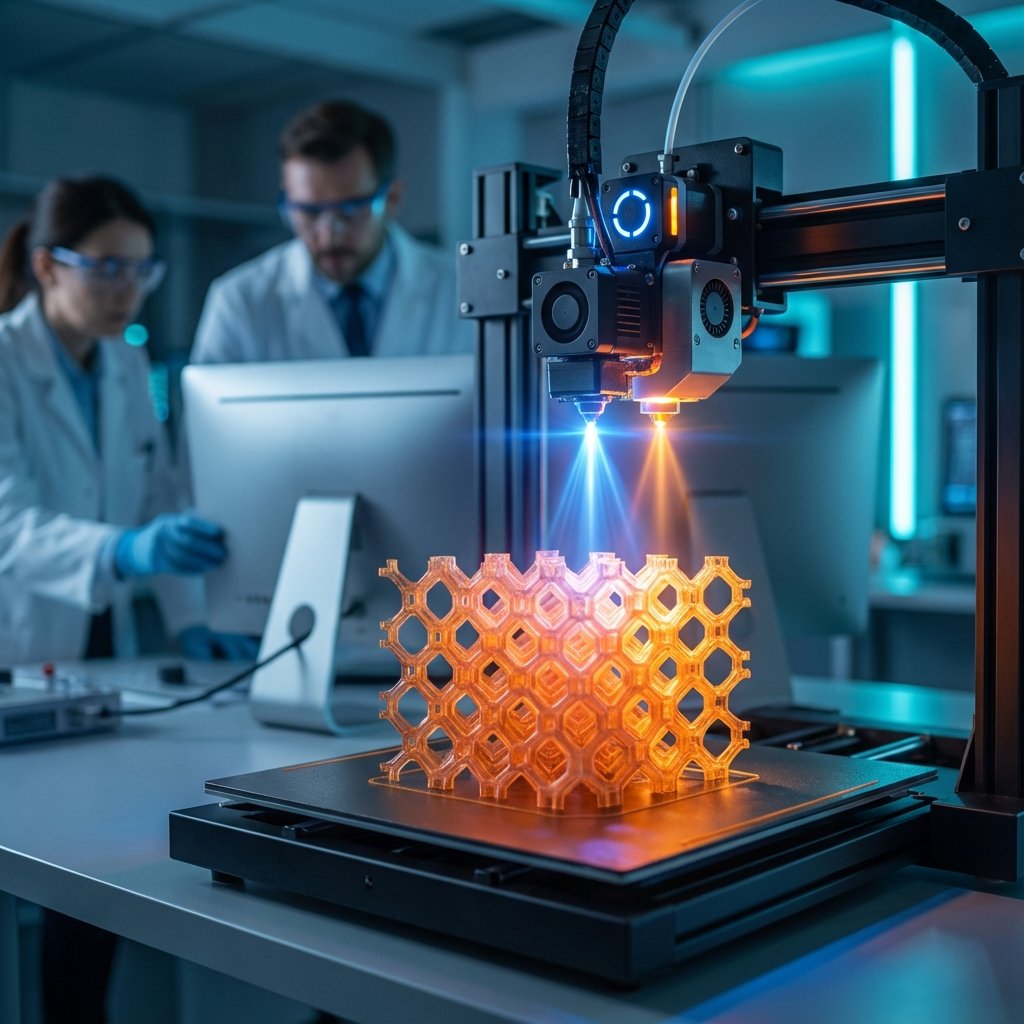

The manufacturing landscape is undergoing a seismic shift. For decades, terms like „injection molding” and „extrusion” dominated the production floor. While these methods remain vital, a new contender has graduated from the prototyping lab to the full-scale production line: 3D Printing, also known as Additive Manufacturing (AM).

Specifically, the combination of AM technology with advanced high-performance polymers is unlocking possibilities that were previously deemed impossible. It’s not just about making plastic trinkets anymore; it’s about creating flight-critical aerospace components, patient-specific medical implants, and ultra-durable automotive parts.

From Prototyping to Production

Historically, 3D printing was the domain of rapid prototyping. Engineers would print a rough model to test fit and form, then switch to traditional tooling for the final product. Today, that gap is closing.

Advancements in printer accuracy, speed, and—most importantly—material science, have enabled direct digital manufacturing. We can now print end-use parts that rival, and sometimes exceed, the mechanical properties of their injection-molded counterparts.

The Stars of the Show: High-Performance Polymers

Standard PLA and ABS plastics are great for hobbyists, but industrial applications demand more. Enter the super-polymers:

- PEEK (Polyether Ether Ketone): Known for its exceptional thermal stability and chemical resistance. It’s often used as a lightweight replacement for metal in aerospace.

- ULTEM (Polyetherimide): Offers high strength-to-weight ratio and is flame retardant, making it ideal for aircraft interiors and electrical components.

- Carbon Fiber Reinforced Nylon: By embedding carbon fibers into a nylon matrix, manufacturers achieve parts with incredible stiffness and tensile strength, perfect for custom jigs, fixtures, and structural components.

Unmatched Design Freedom

The true power of 3D printing lies in geometric complexity. Traditional manufacturing is „subtractive” (machining away material) or formative (using molds). Both have strict limitations—you need draft angles, you can’t have undercuts without complex sliders, and internal hollow structures are nearly impossible.

3D printing builds layer by layer, freeing designers to create:

* Lattice Structures: Internal honeycombs that reduce weight by 60% while maintaining structural integrity.

* Consolidated Assemblies: Printing a gear system or a nozzle assembly as a single piece, eliminating the need for weak joints and fasteners.

* Topology Optimization: Using AI software to generate organic, bone-like shapes that place material only exactly where stress loads require it.

Real-World Impact

Aerospace

Boeing and Airbus have been pioneers, using printed polymer parts to shave hundreds of kilograms off aircraft weight. Every kilogram saved translates to significant fuel savings over the plane’s lifetime.

Medical

The medical field utilizes biocompatible polymers to print patient-specific guides for surgery, custom prosthetics that fit perfectly, and even porous implants that encourage natural bone growth.

Automotive

Companies like Ford and BMW use high-performance polymer printing not just for parts, but for the factory floor itself—printing custom tools and robotic grippers overnight to adapt to new assembly lines.

The Road Ahead

As we look to the rest of 2026 and beyond, the convergence of AI, material science, and automation will further accelerate this trend. We are moving towards a future of distributed manufacturing, where digital files are sent globally and printed locally, reducing shipping costs and carbon footprints.

The revolution isn’t coming; it’s already here, layer by layer.

Are you leveraging advanced polymers in your manufacturing process? The future might just be one print away.

Parašykite komentarą