Gerai, štai listicle stiliaus straipsnis apie pasaulio ir Europos bioplastikų rinkos augimą, veiksnius ir tendencijas.

## Pasaulio ir Europos Bioplastikų Rinkos Augimas, Veiksniai ir Tendencijos: Top X

Bioplastikai – tai plastikai, pagaminti iš atsinaujinančių biologinių šaltinių, pavyzdžiui, kukurūzų krakmolo, cukranendrių ar celiuliozės. Jų populiarumas sparčiai auga, nes jie siūlo alternatyvą tradiciniams, naftos pagrindu pagamintiems plastikams, mažinant priklausomybę nuo iškastinio kuro ir skatinant tvaresnę ateitį. Šiame straipsnyje aptarsime bioplastikų rinkos augimą pasauliniu ir Europos mastu, pagrindinius augimo veiksnius ir ateities tendencijas.

### 1. Bioplastikų Rinkos Augimas: Spartus Šuolis

**Atsakymas į klausimą:** Pasaulio bioplastikų rinka nuolat auga, o prognozuojama, kad iki 2027 metų pasieks kelis milijardus JAV dolerių.

Pastaraisiais metais bioplastikų rinka patyrė reikšmingą augimą. Augimas skatinamas didėjančio vartotojų ir verslo sąmoningumo apie aplinkosaugos problemas. Reguliavimo iniciatyvos, tokios kaip plastiko mokesčiai ir draudimai, taip pat vaidina svarbų vaidmenį.

**Pro Tip:** Stebėkite naujausias rinkos ataskaitas, kad gautumėte tikslią informaciją apie augimo tempus ir prognozes.

### 2. Europos Rinkos Lyderystė: Bioplastikų Hotspot’as

**Atsakymas į klausimą:** Europa yra viena iš pirmaujančių regionų bioplastikų gamyboje ir vartojime pasaulyje.

Europa, ypač Vokietija, Italija ir Prancūzija, yra bioplastikų rinkos lyderė. Stiprus Europos Sąjungos (ES) dėmesys tvarumui, aplinkosaugos politika ir didelis vartotojų sąmoningumas skatina bioplastikų paklausą regione.

**Pro Tip:** Orientuokitės į ES reguliavimo pokyčius, susijusius su plastiku, nes jie tiesiogiai veikia bioplastikų rinką.

### 3. Pagrindiniai Augimo Veiksniai: Vartotojų Sąmoningumas ir Reguliavimas

**Atsakymas į klausimą:** Pagrindiniai bioplastikų rinkos augimo veiksniai yra didėjantis vartotojų sąmoningumas apie aplinkosaugos problemas ir griežtėjantis reguliavimas, skatinantis tvaresnes alternatyvas.

Pagrindiniai veiksniai, skatinantys rinkos augimą:

* **Didėjantis vartotojų sąmoningumas:** Vartotojai vis labiau ieško tvarių produktų, o tai skatina bioplastikų paklausą.

* **Griežtėjantis reguliavimas:** Draudimai naudoti vienkartinius plastikinius gaminius ir mokesčiai už plastiką skatina verslus pereiti prie bioplastikų.

* **Įmonių tvarumo iniciatyvos:** Daugelis įmonių siekia sumažinti savo poveikį aplinkai, įskaitant bioplastikų naudojimą savo pakuotėse.

**Pro Tip:** Stebėkite vartotojų tendencijas ir reguliavimo pokyčius, kad suprastumėte, kaip šie veiksniai veikia rinkos augimą.

### 4. Tendencijos: Naujovės ir Naujos Taikymo Sritys

**Atsakymas į klausimą:** Svarbios tendencijos apima naujų bioplastikų kūrimą, jų pritaikymą platesniam spektrui produktų ir didesnį dėmesį perdirbamumui ir kompostavimui.

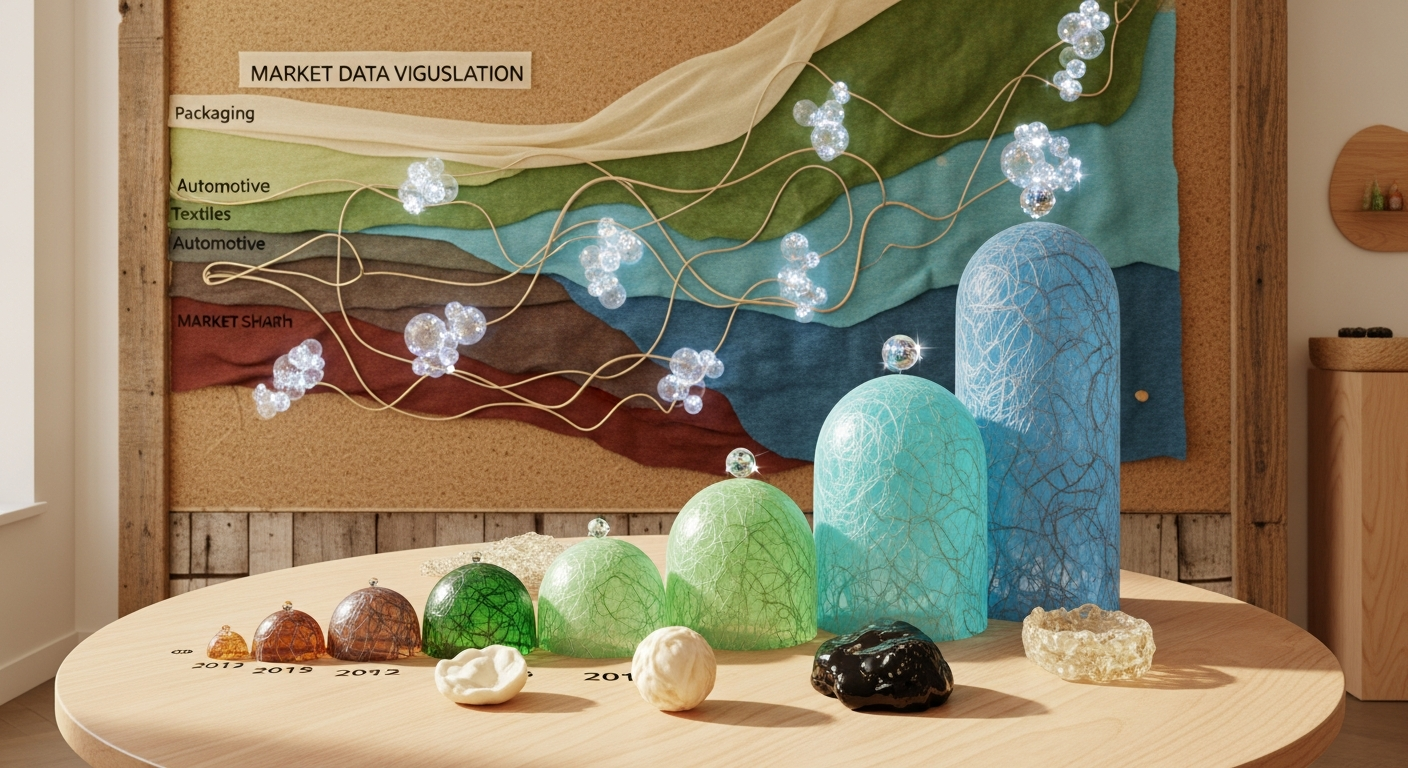

Pagrindinės bioplastikų rinkos tendencijos:

* **Naujų bioplastikų kūrimas:** Tyrimai ir plėtra siekia sukurti naujus bioplastikus su geresnėmis savybėmis ir platesniu panaudojimu.

* **Pakavimo pramonė:** Bioplastikai vis dažniau naudojami maisto pakuotėms, gėrimų buteliams ir kitoms pakavimo reikmėms.

* **Žemės ūkis ir sodininkystė:** Bioplastikai naudojami plėvelėms, mulčiui ir kitoms žemės ūkio reikmėms.

* **Tekstilės pramonė:** Vis daugiau bioplastikų integruojama į tekstilę.

* **Perdirbimas ir kompostavimas:** Didelis dėmesys skiriamas bioplastikų perdirbamumui ir kompostavimui, siekiant užtikrinti jų tvarumą.

**Pro Tip:** Stebėkite naujausias technologijas ir naujoves bioplastikų gamybos srityje, kad suprastumėte rinkos ateitį.

### 5. Iššūkiai: Kaina ir Veikimas

**Atsakymas į klausimą:** Pagrindiniai iššūkiai yra didesnė kaina, palyginti su tradiciniais plastikais, ir kartais mažesnis veikimas, priklausomai nuo naudojimo srities.

Nepaisant didelio augimo, bioplastikų rinkai vis dar kyla iššūkių. Dauguma bioplastikų yra brangesni nei tradiciniai plastikai, o kai kurių bioplastikų veikimas nėra toks geras, kaip tradicinių plastikų.

**Pro Tip:** Sekite bioplastikų gamybos sąnaudų mažinimo iniciatyvas.

### Apibendrinimas: Top 3

| Savybė | Bioplastikas | Tradicinis Plastikas |

|—————|————————–|—————————-|

| Šaltinis | Atsinaujinantys šaltiniai | Naftos pagrindo žaliavos |

| Poveikis Aplinkai| Mažesnis | Didesnis |

| Kaina | Didesnė | Mažesnė |

Apibendrinant, bioplastikų rinka auga dėl didėjančio vartotojų sąmoningumo ir griežtėjančio reguliavimo. Nors iššūkių vis dar yra, naujovės ir naujos taikymo sritys žada šviesią ateitį šiam tvarumui orientuotam pramonės segmentui.